The insole materials influence the plantar pressure distributions in diabetic foot with neuropathy during different walking activities

Muhammad Nouman, Tulaya Dissaneewate, Wipawan Leelasamran, Surapong Chatpun

Gait & Posture 74 (2019) 154–161 DOI:10.1016/j.gaitpost.2019.08.023

1. 서론 및 배경

-당뇨 환자의 약 15%가 족부 궤양에 직면하고 있으며, 80% 이상이 매년 재발하는 당뇨발 궤양에 직면하고 있다. 신경병성 당뇨발에서 비정상적인 족저압을 관리하기 위하여 custom-made insole 이 제작되고 있다. Multiple layer 및 다른 경도를 가진 custom-made insole은 peak plantar pressure와 contact area에 다른 영향을 미칠 것이다. 따라서 상기 연구에서는 신경병증이 있는 당뇨발에서 보행 시 maximum peak plantar pressure, pressure-time-integral, pressure distribution, contact area, center of pressure를 측정하여 Multiple layer custom-made insole 소재의 효과를 조사하고자 하였다.

2. 대상 및 방법

2.1. Participants

- 16명의 diabetic neuropathic patients (나이: 40-60, 제2형 당뇨병)

- Forefoot에 Callus가 있거나 또는 변형이 있는 환자들(hallux valgus, hammer toe, mallet toe)

- 10g monofilament에 발의 감각이 저하되어 있는 경우

2.2. Custom-made insole

- Insole에 사용된 재료: multifoam 5 mm thick (30 °Shore A hardness), Plastazote® 8 mm (25 °Shore A hardness), Microcellular rubber 10 mm (70 °Shore A hardness)

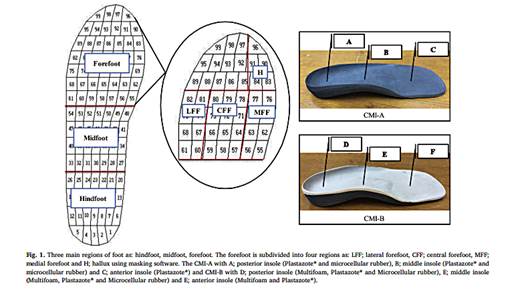

- 2가지 종류의 custom-made insole이 제작됨. (Fig. 1)

1) two-layer insole (Plastazote® and microcellular rubber)___CMI-A

2) three-layer insole (Multifoam, Plastazote® and microcellular rubber)___ CMI-B

2.3. Evaluation of custom-made insoles

- Plantar pressure는 CMI-A 및 CMI-B를 신고 개인이 선택한 속도로 3가지 보행 활동 동안 기록함: level walking (10 m), ramp walking (angled 8.04°) for 4 m, 10 steps stair walking (step height 17.5 cm and 29 cm deep)

- Pedar-X® mobile in-shoe system (Novel GmbH, Munich, Germany)

- Maximum peak plantar pressure, pressure-time integral, pressure distribution, contact area, center of pressure 측정함.

- Foot plantar surface는 3개의 구역(hindfoot, midfoot, forefoot)으로 분류함. 특히 forefoot은 hallux, medial forefoot, central forefoot, lateral forefoot으로 세부 분류함. (Fig. 1)

3. 결과

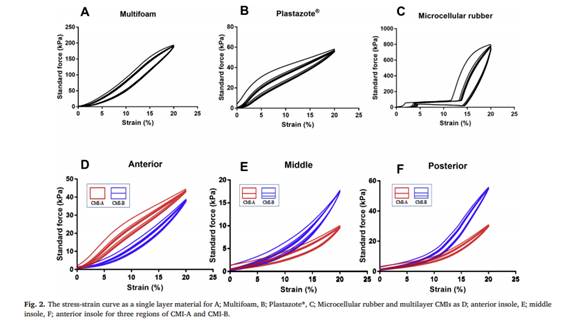

3.1. Compression testing of custom made insoles (Fig. 2)

- 3가지 재료 모두 viscoelastic 성질을 가지고 있었다. Plastozote®가 multiform과 microcellular rubber 보다 더 부드러웠다.

- J-곡선을 나타내는 CMI-B와 비교하였을 때, CMI-A 앞부분에서 상당량 stress 증가를 나타내는 S-곡선을 보였다.

- CMI-A는 CMI-B에 비해 insole 앞부분에서 에너지 흡수율이 더 높았다.

- CMI-B는 CMI-A에 비해 insole 중간과 뒷부분에서 더 높은 에너지 return을 보여주었다.

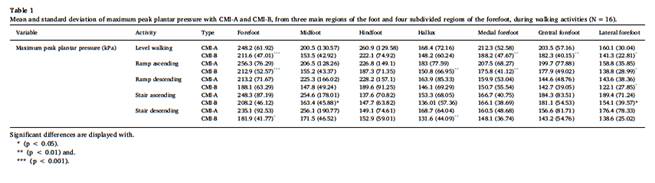

3.2. Influence on maximum peak plantar pressure (Table 1)

- CMI-A는 모든 활동영역에서 CMI-B에 비해 압력이 증가하였다.

- CMI-B: Forefoot의 maximum peak plantar pressure가 CMI-A에 비해 level walking시14%, ramp ascending시 16% 감소하였다. Midfoot의 maximum peak plantar pressure가 CMI-A에 비해 stair ascending시 36% 감소하였다.

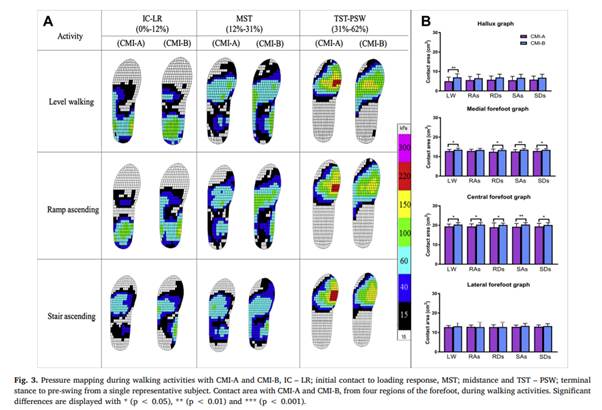

3.3. Pressure distribution and contact area (Fig. 3)

- 대체로 CMI-B에서 모든 활동시 압력이 잘 분산되었다.

- CMI-A는 hallux 및 medial forefoot 부위에서의 족저압이 높게 관찰되었으며, CMI-B는 hallux를 포함하여 metatarsal heads 부위에서의 족저압이 낮게 관찰되었다.

- CMI-B: 모든 활동 영역에서 CMI-A에 비해 forefoot의 contact area가 증가되어 있었으며, 특히 level walking시 13% 증가하였다. Medial & central forefoot contact area는 CMI-A에 비해 stair ascending시 7%, ramp descending시 6% 증가하였다.

4. 결론

CM-B 사용시 level walking, ramp ascending, stair descending에서 CMI-A에 비해 forefoot의maximum peak pressure가 감소하였다. 즉, Plastazote®와 microcellular rubber 위에 추가적인 multifoam층을 깐 multiple layer custom-made insole은 forefoot의 peak plantar pressure 감소에 효과적이었으며, 이는 신경병증이 있는 당뇨발에서 level walking과 ramp ascending 활동 시 족저압 분포가 개선됨을 보여주었다.